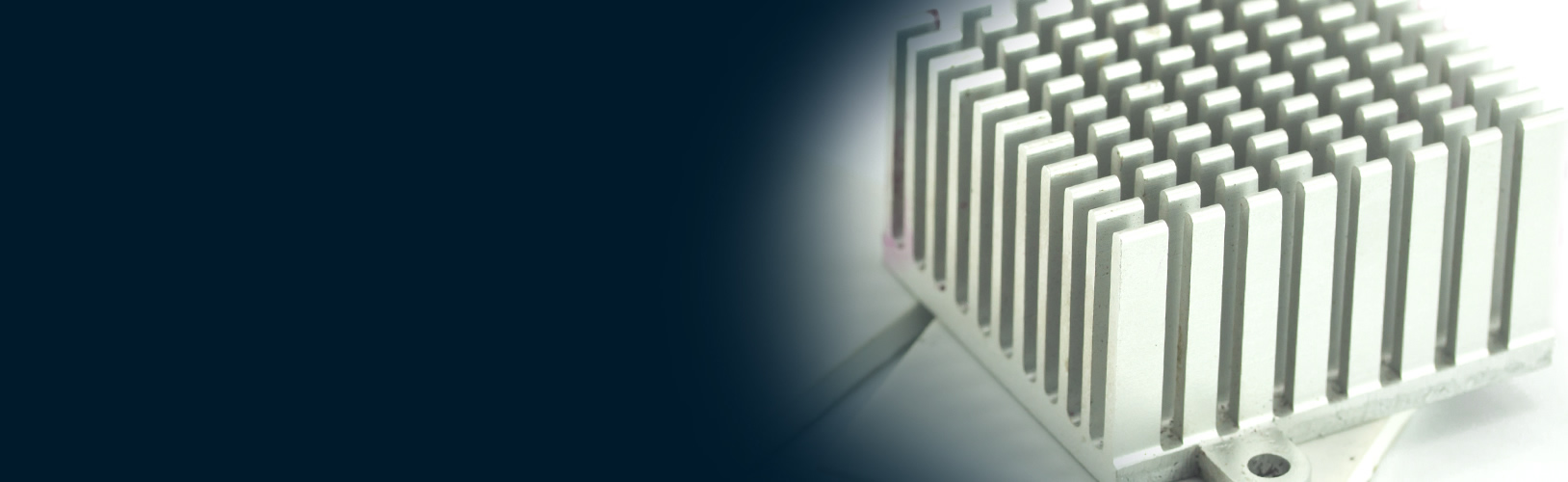

Cold Forging – Pin & Fin HeatsinksThe Sourcing Store supply cold forged pin and fin heatsinks.

Cold Forging – Pin & Fin HeatsinksThe Sourcing Store supply cold forged pin and fin heatsinks.

We supply cold forged pin and fin heatsinks to our customer drawings and specifications. The process of cold forging the heatsinks under high pressure eliminates porosity and prevents air bubbles giving a clear thermal advantage over diecast or extruded heatsinks, The material used is almost pure aluminium which has very good thermal conductivity compared with other grades of aluminium. The round pin heatsinks work particularly well for natural convection in circumstances of low airflow. Pin and fin heatsinks of all shapes and varying sizes can be produced economically and accurately with secondary machining where required to finish the part with threaded holes and different pin heights etc.